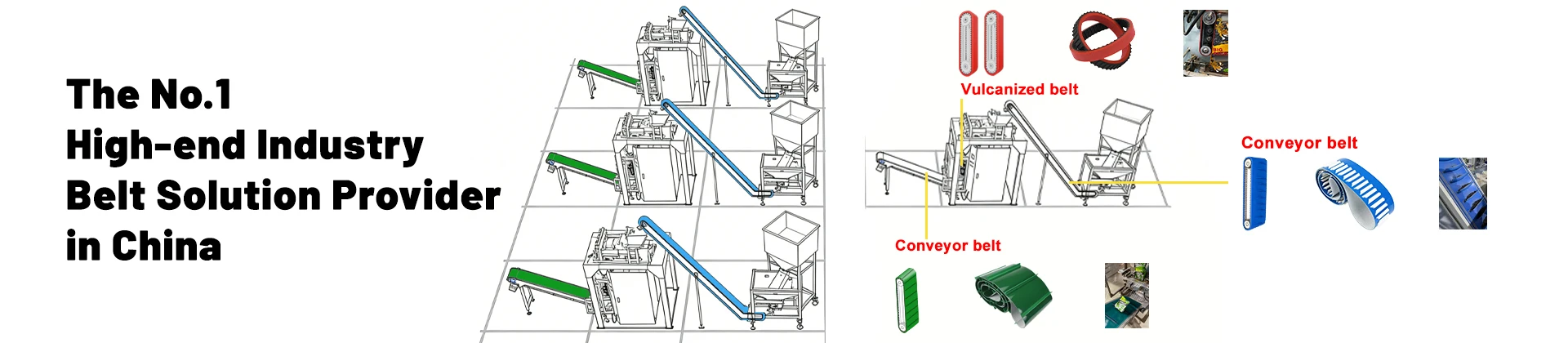

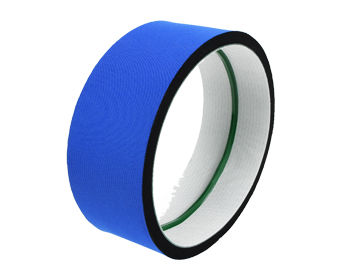

1. Feeding & Bottle Handling | Bottle unscrambler, bottle feed star wheel, bottle separator | Orientation, separation, and buffering of bottles/cans/boxes | Bottle slippage, bottle jamming, uneven spacing | Vulcanized synchronous belt + stops(T10/HTD 5M) | High coefficient of friction, integrated vulcanized stop, wear-resistant |

2. Filling & Capping | Filling machine, capping machine, sealing machine | Precise positioning and synchronous conveying | Positioning misalignment, filling leakage, cap tilting | Seamless vulcanized synchronous belt(T10/HTD 8M) | Zero tooth skipping, high dimensional stability, resistant to cleaning fluids |

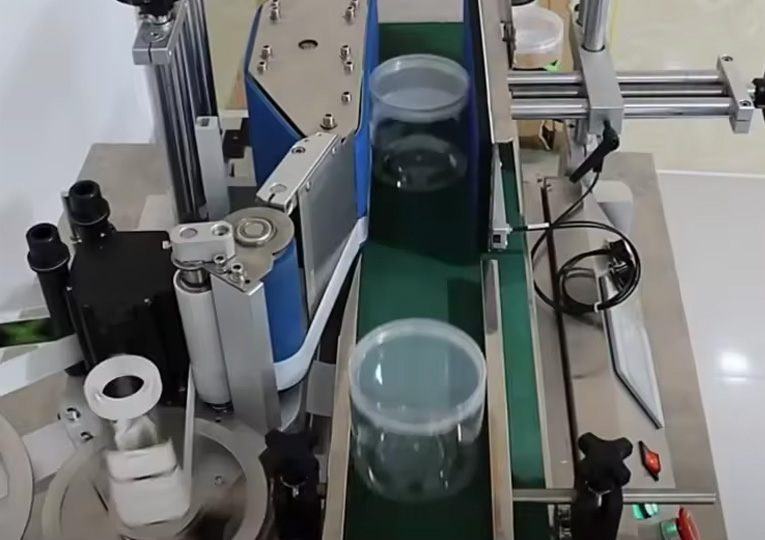

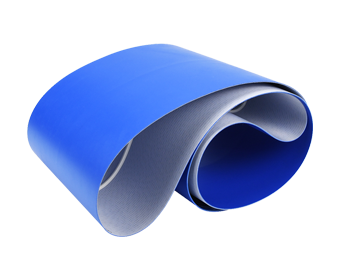

3. Labeling & Coding | Labeling machine, hot melt adhesive labeling, inkjet printer | Stable material conveying and accurate label application | Label misalignment, air bubbles, misaligned coding | Foam tape or Rubber-coated synchronous belt | Flexible cushioning, high fit, antistatic |

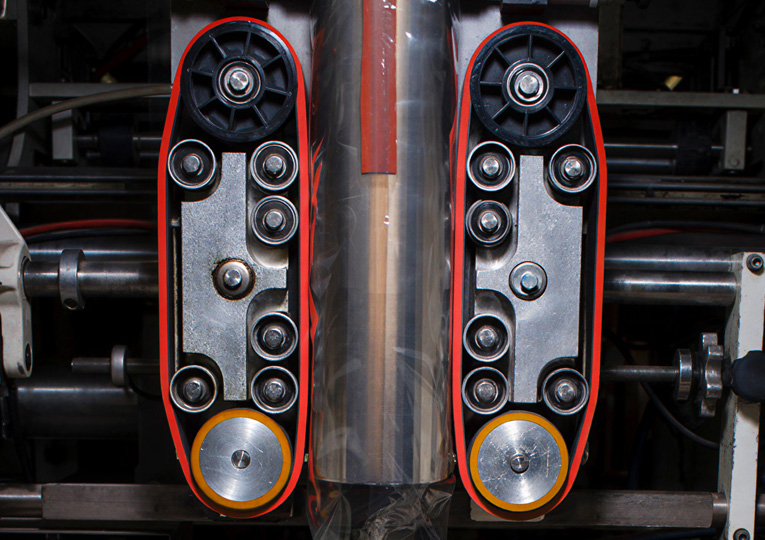

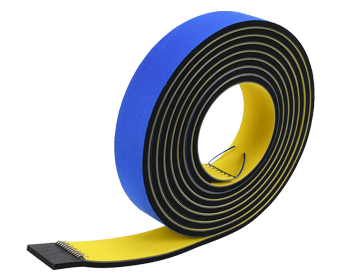

4. Wrapping & Boxing | Pillow packaging machine, cartoning machine, wrapping machine | Film/carton traction and product pushing | Film misalignment, material slippage, box jamming | Rubber-coated vulcanized synchronous belt or Flat belt + stops | Anti-slip surface, oil-resistant, high tensile strength |

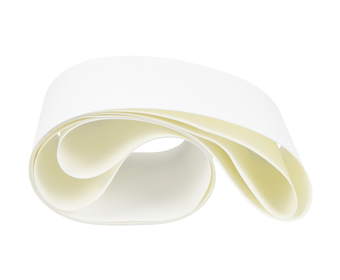

5. Packing & Palletizing | Case packing machine, robotic gripper area, palletizing line | Heavy-duty conveying and box positioning | Belt stretching, joint breakage, box displacement | Steel wire tensile vulcanized synchronous belt(L/HTD 8M) | High tensile strength, seamless, impact-resistant |

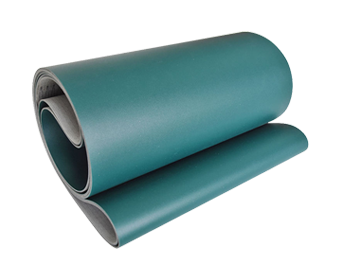

6. Inspection & Rejection | Metal detector, X-ray machine, vision inspection, rejection device | Smooth and uniform speed conveying with precise triggering | Vibration interference detection, inaccurate rejection | Low-noise flat conveyor belt(PU/PVC) | Smooth surface, non-magnetic, FDA certified (food grade) |

7. Shrink Packing & Cooling | Heat shrink oven, cooling tunnel | High-temperature resistant continuous conveying | Belt deformation, aging and cracking | High-temperature resistant conveyor belt(Silicone/Teflon/HNBR synchronous belt) | Temperature resistance 150°C+, dimensional stability |

8. Secondary Packaging & Bundling | Automatic strapping machine, stretch wrapping machine | Synchronous box positioning and strapping | Box sliding, strapping misalignment | High-friction PU flat belt or synchronous belt with stops | Controllable surface roughness, resistant to binding friction |