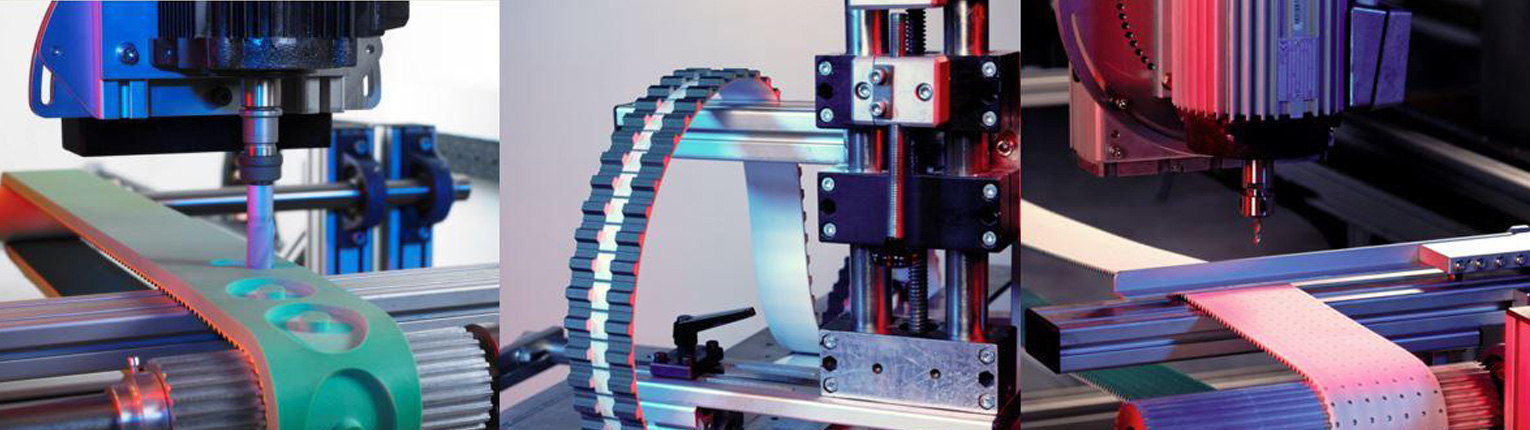

Mold Design and Manufacturing

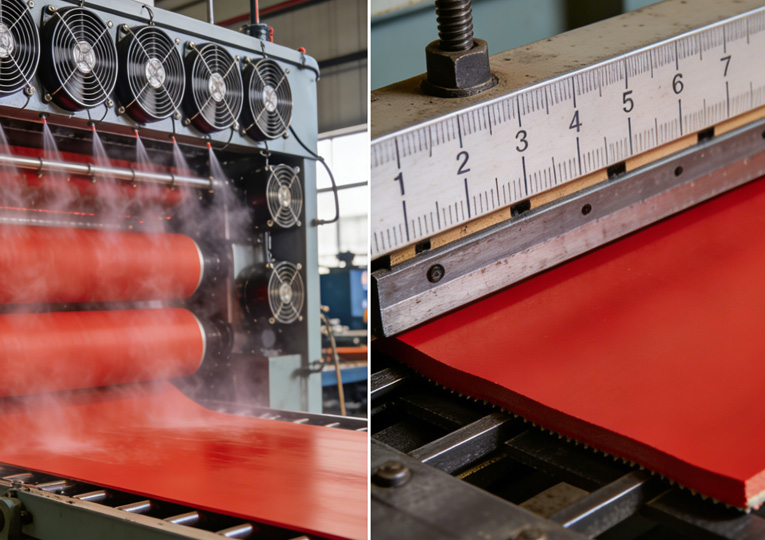

We possess sophisticated mold design and rapid manufacturing capabilities, ensuring that every belt has precise tooth profiles and superior transmission performance.

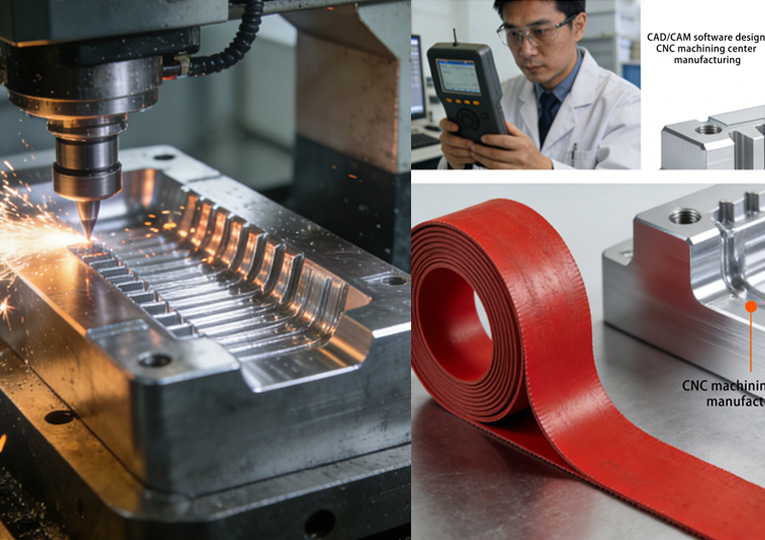

- Precise design using CAD/CAM software ensures key parameters such as tooth profile and pitch meet standards.

- Molds are manufactured using CNC machining centers, guaranteeing dimensional tolerances within ±0.02mm.

- Strict quality inspection ensures flawless molds with a long service life.